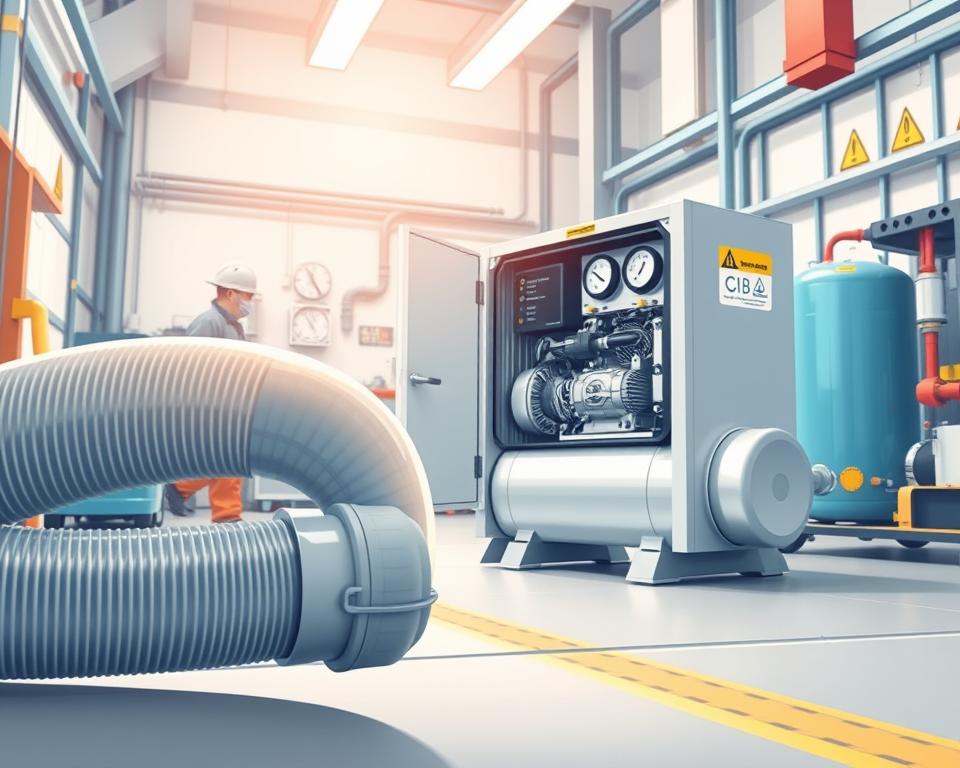

PVC Pipe for Air Compressor Lines: Your Complete Guide

You might be surprised to learn that a failure in a compressed air system can unleash power on par with dynamite. Countless operations remain oblivious to the risks of certain piping systems they employ. Read on to discover why PVC air line choices demand top-tier safety.

Despite growing interest in certain materials, OSHA strictly prohibits their use in above-ground applications. Over time, exposure to oils and temperature changes weakens them, leading to catastrophic failures. Safe-rated pressures can still result in deadly bursts.

Installation Parts Supply provides safer options such as aluminum piping. Spending on the right materials prevents OSHA penalties and protects employees. Let’s explore how to build a safer system.

Salient Features

- OSHA prohibits specific piping for air lines because of blast hazards.

- Pressure ratings drop as temperatures fluctuate.

- Long-term exposure makes pipes prone to brittle breaks.

- Aluminum piping offers a safer alternative.

- Spending on correct materials avoids penalties and injuries.

The Risks of PVC in Air Compressor Lines

Manufacturers explicitly warn against using some plastics for high-energy applications. Compressed air carries destructive energy; a burst is like a dynamite blast. Select your piping wisely to avoid deadly failures.

- Brittleness: Below-freezing conditions render PVC dangerously brittle.

- Adhesive failures: Joints weaken when exposed to compressor oils or temperature swings.

- Misleading ratings: Pressure capacity drops 50% at 110°F—most workshops exceed this.

OSHA cites a $110,000 fine after a facility’s piping shattered, injuring workers. The “heat of compression” further reduces safe operating limits, a factor often overlooked in ratings.

“Above-ground use of certain plastics for compressed air violates OSHA standards due to explosion risks.”

Metal alternatives fail more predictably, bending rather than fragmenting. Fragments from PVC blasts can hurl past 50 feet, embedding dangerously.

Constant temperature swings in shops speed up pipe aging. A decade’s UV and chemical attack weakens plastic, so small leaks too often balloon into disasters.

Best Materials Instead of PVC for Air Lines

Aluminum piping systems outperform traditional options in both safety and efficiency. Black pipe vs. aluminum: aluminum wins with 90% fewer leaks. Aluminum’s lightness and anti-rust traits prolong system life.

Modular aluminum setups save time—no threading required. Installation Parts Supply stocks ready-to-snap aluminum modules. A car plant saw a 40% drop in labor expenses after aluminum installation.

- Copper: Ideal in sterile environments for its germ-killing copper surface. Requires soldering expertise.

- Stainless Steel: Stainless steel stands up to salty, moist conditions.

- ABS/HDPE: Plastic choices like ABS or HDPE handle harsh chemicals.

“Our aluminum retrofit reduced energy waste by 15%—paying for itself in 18 months.”

Don’t ignore torque specs. Too tight splits fittings; too loose lets air escape. Follow manufacturer specs—typically 25–30 ft-lbs for aluminum joints.

Use NSF-certified materials when air quality is critical. Always match materials to your environment’s demands.

Selecting the Best Air Compressor Piping

Balance budget, safety, and performance when choosing pipe. One plant slashed $12k per year by adopting aluminum lines. Follow these tips to pick wisely.

| Material | Cost (per ft) | Maintenance | ROI Time |

|---|---|---|---|

| Aluminum | $8.50 | Low | 18 months |

| Black Pipe | $5.00 | High | N/A |

| Copper | $10.20 | Medium | 24 months |

Don’t ignore thermal limits. Plastics fail under 32°F; aluminum works from -40°F to 200°F. For chemical-heavy environments, stainless steel resists solvents.

Pro Tip: Compute ROI based on compressed-air leakage. A 10% air leak in 50 HP equals about $3,500 annually.

- Ensure your pipe PSI rating exceeds system pressure.

- Keep records of inspections and tests to satisfy OSHA.

- Contact Installation Parts Supply for a no-cost audit.

“Our aluminum retrofit cut energy waste by 15%—paying for itself in 18 months.”

Hire pros for big installs to guarantee airtight connections. Check warranties—some pipes include decade-long coverage.

Final Thoughts

Smart material selection protects life and wallet. Ninety-two percent of pipe failures occur in aging lines, frequently causing injuries. Pick aluminum for near-perfect reliability.

Remember:

- Avoid brittle materials that shatter under pressure.

- Opt for corrosion-resistant metals like aluminum or stainless steel.

- Ignoring standards invites fines and insurance headaches.

Time to make the switch? Installation Parts Supply provides same-day quotes and limited-time discounts on starter kits. Download our free maintenance template or call for emergency replacements.

Commit to safer piping today—your team’s safety depends on it.